UPVC pipes are widely used in households, industries and construction sites. The GREMAX have numerous advantages over traditional metal or concrete pipes, such as lightweight, corrosion-resistant and durable. However, to ensure the performance and longevity of UPVC pipes, proper storage precautions need to be taken. We will discuss the innovation, safety, use, how-to-use, service, quality, and application of UPVC pipes.

Advantages of UPVC Pipes

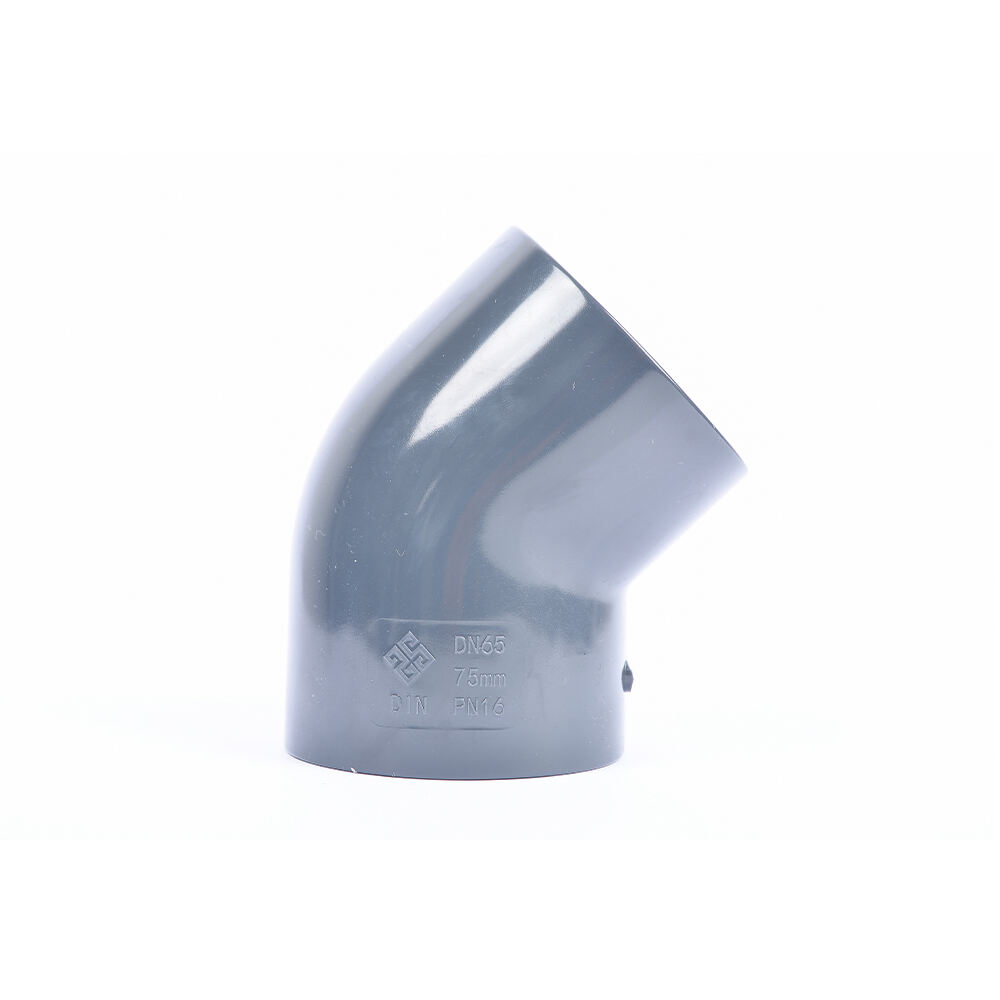

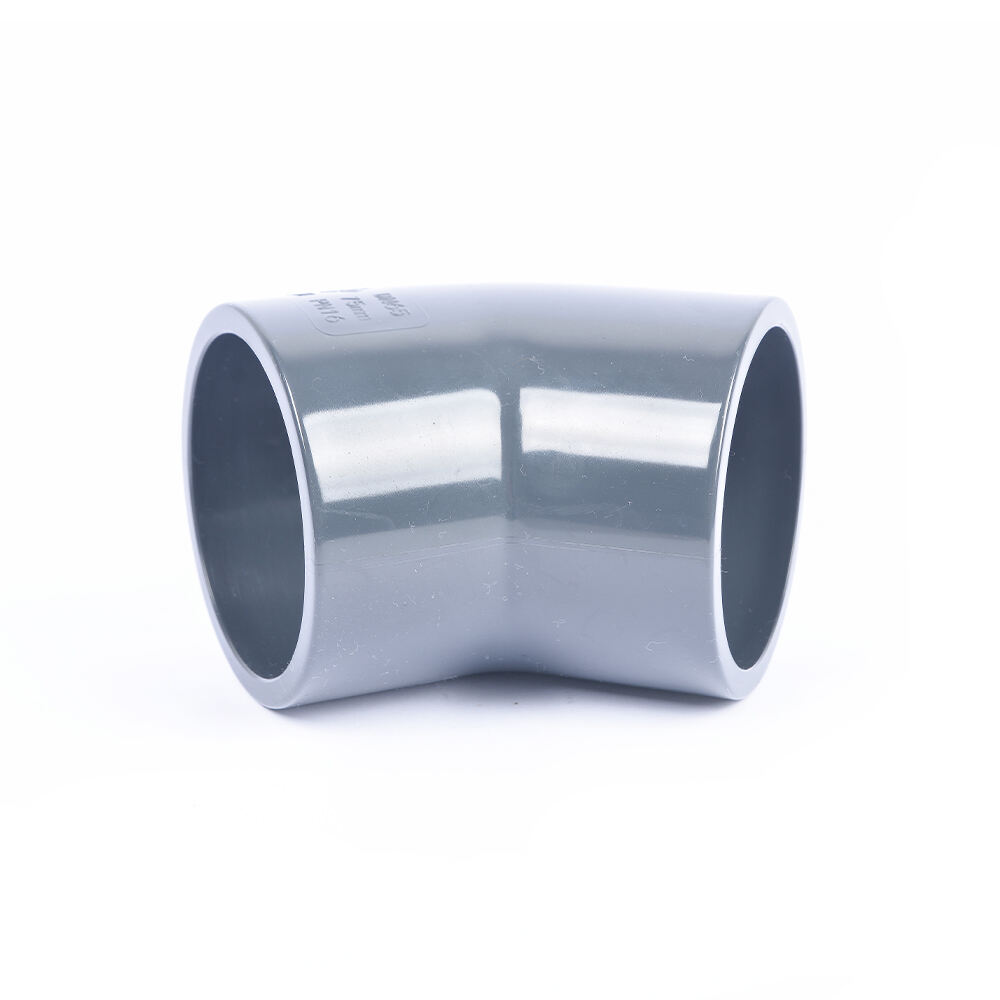

UPVC pipe is a material that thermoplastic which resistant to chemicals, UV rays and weather. Due to its corrosion-resistant nature, UPVC pipes are ideal for conveying various fluids, including hot and water that sewage that cold chemicals, among others. Moreover, they are lightweight and easy to install, leading to lower labour and transportation costs. UPVC Pipe Fitting also have a longer shelf life than traditional pipes like concrete or metal, which makes them more economical and a choice that preferable.

Innovations in UPVC Pipes

With growing demand and the need to meet concerns that are environmental UPVC pipes have gone through several innovations Manufacturers have produced UPVC pipes with higher heat resistance, smoother interior surfaces and noise reduction features. Modern CPVC Pipe are colour-coded for different applications, such as yellow for gas and blue for potable water. Moreover, UPVC pipe manufacturers have started using additives that are lead-free provide safe and pipes that are eco-friendly.

Safety Precautions when UPVC that using Pipes

UPVC pipes are much safer than traditional pipes made of asbestos and lead. As they are a material that thermoplastic UPVC pipes do not degrade and release chemicals that are harmful exposed to heat. However, proper measures need to be taken when handling and using UPVC pipes. It is essential to wear gloves and eye protection when using a saw or cutting a UPVC pipe and to avoid bending the pipes beyond their recommended radius.

How to Use UPVC Pipes

UPVC pipes are versatile and can be used for several applications, such as plumbing, irrigation, sewage, and conduit that electrical. Before installation, it essential to clean the pipes and fittings to remove any dirt, oil or debris. Using a pipe cutter or a saw, cut the UPVC pipe to the desired length. The next step to install the fittings using a solvent cement, which creates a strong and joint that reliable. After assembling the UPVC pipes, leave them to cure for several hours before using them.

Service and Quality of UPVC Pipes

The service life of UPVC pipes largely depends on the quality of manufacturing, installation, and maintenance. Therefore, buying high-quality UPVC pipes from a manufacturer that reputable essential. Such pipes will have a longer shelf life and less chance of failure or leakage. Moreover, manufacturers offer warranties on their products, which give customers confidence in the quality of their purchases.

Applications of UPVC Pipes

UPVC pipes have numerous applications in households, industries and agriculture. Some applications that are common water distribution and supply, sewage and wastewater management, and irrigation systems. UPVC pipes are also used for electrical wiring and cable conduit piping. The

flexibility of CPVC Pipe Fitting makes them useful in retrofitting pipes that

are old thereby reducing the need for new installations.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

BE

BE

KA

KA

PA

PA

XH

XH